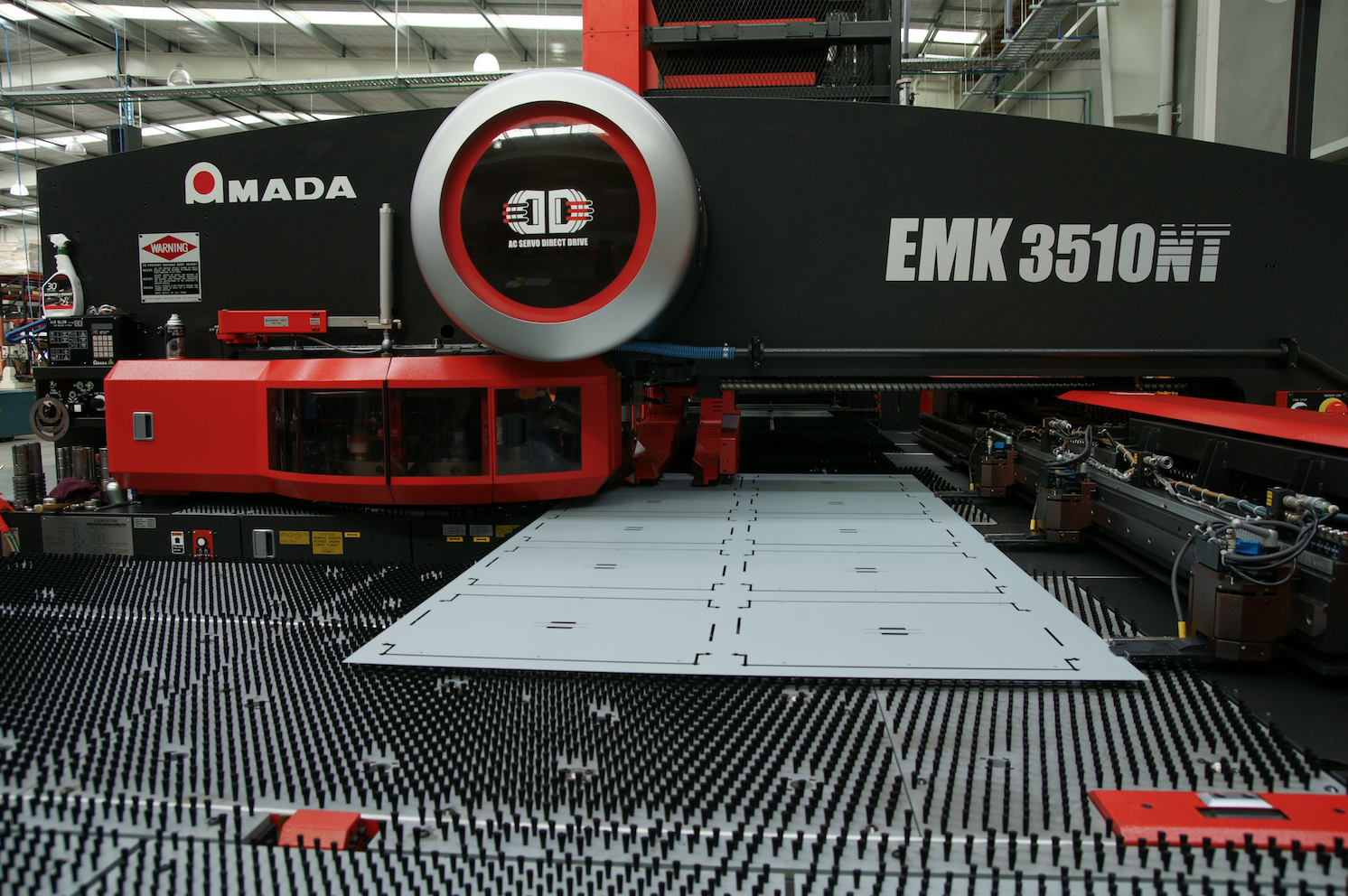

Multiple turret punches and a vast selection of tooling to produce any product or part

With three Amada turret punches at our disposal we have the capacity to take on large volume production jobs and meet any short leads times that may be demanded by our customers. We have a vast selection of tooling which includes many specialised shapes and forms. This enables us to offer many different options for producing parts which may require holes, forms, bursts or tapping.

With today’s market being so competitive, efficiency is at a premium and our turret punches have several cutting edge features that help us reduce costs. Our machines are able to run lights out/unmanned which allows us to offer a more competitive rate for high volume production runs.

The parts take out feature of our AMADA EMTK machine minimises the downtime between punching and the next operation required.

We have 3 x Amada Turret Punches. Between them we can accommodate the following sheet sizes and thicknesses.

General Turret Punch Specifications

Mild Steel – Up to 3mm

Stainless Steel – Up to 3mm

Aluminium – Up to 5mm

Countersinking, forming, tap, louvring, slotting and recessing,

Amada EMZ 3610NT

Maximum Sheet Size: 3050 x 1550mm

Maximum Thickness Mild Steel: Up to 3mm

Maximum Thickness Stainless Steel: Up to 3mm

Maximum Thickness Aluminium: Up to 6mm

EMTK 3510NT Turret Punch

Maximum Sheet Size: 2440 x 1220mm

Maximum Thickness Mild Steel: Up to 3mm

Maximum Thickness Stainless Steel: Up to 2.5mm

Maximum Thickness Aluminium: Up to 6mm